C.A.C.® S200

(without corkscrew)

This knife is a true concentrate of all the cutting-edge technologies that one would expect from an operational knife.

The blade is made of Nitrox®, can be chosen in Mixed (smooth + tightening) or Smooth version. This version of the CAC knife features a strap cutter and does not have a corkscrew.

Weight: 195g

Blade length: 85mm

Total length closed: 145mm

Knife sold without Forks and without sheath.

Personalize your knife with a first name, a text and make your CAC® a unique knife!

(without corkscrew)

Technical specifications

(in grs)

195

55

Serrated

17

G10

With

Without

Axe_mobile

yes

Yes

(Pattern/finish)

Toxifié

(mm)

85

(mm)

145

Nitrox

The accessories

CAC safety axis for after-sales service or replacement

Folding diamond sharpener

C.A.C® - Maintenance Kit

Forks Black - C.A.C.®

Blade

Smooth cut and serrated section

Window breaker

Tungsten Carbide Ball

Strap cutter

To cut seat belts or paracord

Belt Clip

Reversible for right or left handed wear.

Hole

For halyard or strap

Opening mechanism

Secure blade locking by movable axis. Ambidextrous.

The history of C.A.C.®

This knife is our company's response to the request expressed by the French army through very precise specifications: to design a robust, ambidextrous field knife with one-handed opening and closing. .

The C.A.C.®, or Combat Assistance Campagne, is the result of a collaboration between TB Outdoor and Philippe Perotti, former French special forces.

The C.A.C.® was officially selected by the French army in 2016, over numerous competing products for its performance, its robustness, its uncompromising manufacturing quality, and its price.

Since 2018, the C.A.C.® has been widely deployed among our military forces and contributes daily to their security.

The C.A.C.® is the third iteration of the “Campaign knife” that Tarrerias - Bonjean designs and manufactures for the French army. Its uncompromising design, lightness and robustness make the C.A.C.® an exceptional knife. Much more technical and ambitious than its predecessors, the C.A.C.® is TB's response to the request expressed by the French army, namely, to design a robust, ambidextrous knife that can be opened and closed with one hand. . To create this exceptional knife, TB collaborated with Philippe Perotti, formerly of the French special forces and author of dozens of books on shooting and its instruction. Its recognized experience in hand-to-hand combat has made it possible to maximize the effectiveness of the knife's use to make the C.A.C.® the ideal companion for our troops in all theaters of operations. The C.A.C.® locking mechanism is extremely durable and ensures flawless blade locking in the open position. The particularity of the C.A.C.® blade is that it is made with stainless steel doped with nitrogen, Nitrox®. Our production site and our engineers actively participated in the development trials of this steel with its particular formulation. A stainless steel doped with nitrogen during its manufacture to replace part of the carbon. This steel gives the blade a particularly high corrosion resistance capacity, especially since the blade is coated with a PVD coating which further accentuates this resistance.

Cutting capacity is also a strong point of this steel which combines flexibility and high resistance.

TB has also integrated the secure blade locking mechanism by movable axis into the C.A.C.®. This mechanism is extremely robust and ensures flawless blade locking in the open position. The C.A.C.® was officially selected for its performance, robustness, quality and price by the French army in 2017.

Perfectly resistant to corrosion, the blade is made of Nitrox®, the edge of which is smooth or mixed smooth + serrations.

The C.A.C.® also has a window breaker, a corkscrew (depending on model) and a reversible belt clip. It is a true concentrate of all the cutting-edge technologies that one can expect from an operational knife.

The handle is made up of two polymer plates loaded with glass fibers. These plates are screwed to the mechanics by stainless steel screws, one of which cleverly houses a strap cutting blade. This curved, interchangeable blade is designed to cut straps, ropes and seat belts to facilitate extraction in the event of an accident.

C.A.C.® is also available in Fluorescent Yellow which reacts intensely to UV light so that it can be found in difficult environments and in the dark.

Many optional accessories are available.

Its variations

The C.A.C.® is a multifunctional knife designed for maximum adaptability. Initially, we designed the knife with handle plates made of PA6, a polymer reinforced with glass fibers to improve its robustness. The PA6 FV has astonishing characteristics in terms of resistance to deformation and shock absorption, making it ideal for the most demanding conditions of use.

However, we have recognized our customers' interest in producing individually machined G10 sleeve inserts in solid blocks. G10 is a composite material based on fiberglass, impregnated with epoxy resin. This material is renowned for its high resistance to humidity, heat, chemicals, and for its exceptional dimensional stability.

The C.A.C.® is a multifunctional knife designed for maximum adaptability. Initially, we designed the knife with handle plates made of PA6, a polymer reinforced with glass fibers to improve its robustness. The PA6 FV has astonishing characteristics in terms of resistance to deformation and shock absorption, making it ideal for the most demanding conditions of use.

However, we have recognized our customers' interest in producing individually machined G10 sleeve inserts in solid blocks. G10 is a composite material based on fiberglass, impregnated with epoxy resin. This material is renowned for its high resistance to humidity, heat, chemicals, and for its exceptional dimensional stability.

The C.A.C.® blade

The C.A.C.® blade is made of stainless steel doped with nitrogen, called Nitrox®. Featuring 16% chromium and a carbon content of 0.35%, Nitrox® is easy to sharpen and resists corrosion like few martensitic steels.

We also offer blade alternatives for sale, MOX® steel, Damascus steel among others.

Notice

Caring for your knife

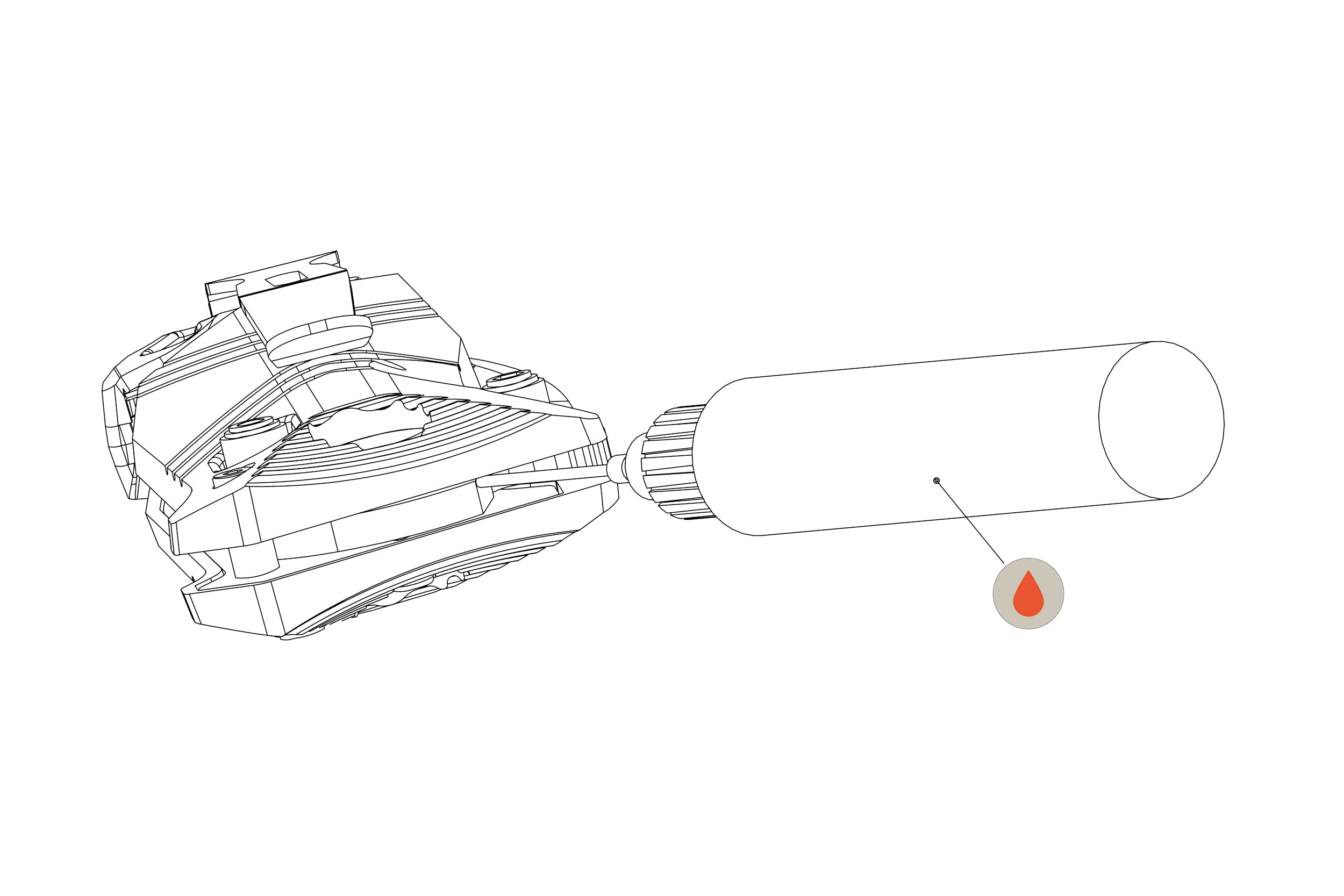

Nitrox® steel was developed, among other things, for its resistance to corrosion. In very humid or salty environments, it is essential to protect your C.A.C.® knife by occasionally applying clear oil to the metal parts.

Occasionally, the belt clip screws may come loose, particularly if you change the clip's mounting direction (right/left). The application of thread lock on the screws, before tightening, is recommended (See supplier's instructions).

Detailed instructions for routine maintenance, sharpening, cleaning, lubricating and adjusting the C.A.C.® are included with each knife. These steps ensure your C.A.C.® remains an effective tool for all your outdoor needs. Take advantage of the robustness, technicality and safety that the C.A.C.® offers, while exploring the fauna and flora with the freedom that only TB Outdoor can offer.

Current operations

The operating settings have been made at the factory and do not require modification on your part. However, some common operations require partial dismantling of the knife. The shiny stainless steel screws, all of the same size (hexagon key T 1.5), are the only ones that need to be operated to carry out the operations below. The other screws, black in color, should not be handled to carry out these operations or to maintain your knife.

Sharpening

It is very easy to maintain the edge of C.A.C.® due to its hardness around 55 HRC. Regularly maintain the edge of your blade before it becomes too damaged. Maintain factory-set sharpening angles that ensure efficient cutting. There are a variety of products available for sharpening your knife. Choose the one you are most comfortable with to carry out this operation.

NEVER SHARPEN YOUR BLADE ON AN ELECTRIC GRINDWHEEL.

The part with serrations can be sharpened with the same accessories, but only on the side opposite the serrations.

An effective cutting tool

Your C.A.C.® knife has been designed to be a real cutting tool. Never use your knife as a screwdriver, crowbar, wood chisel or stamp. Its use for a function other than cutting can lead to irreversible damage.

Clean and lubricate

Always keep the mechanism area clean. Accumulation of dust and/or debris in this area may affect the operation of the blade locking mechanism. For effective cleaning, use warm soapy water, rinse thoroughly with hot water, then blow out and dry the mechanism completely, ideally with compressed air. Finally, apply a protective oily film. For optimal operation, regularly apply a drop of clear oil to the blade rotation axis.

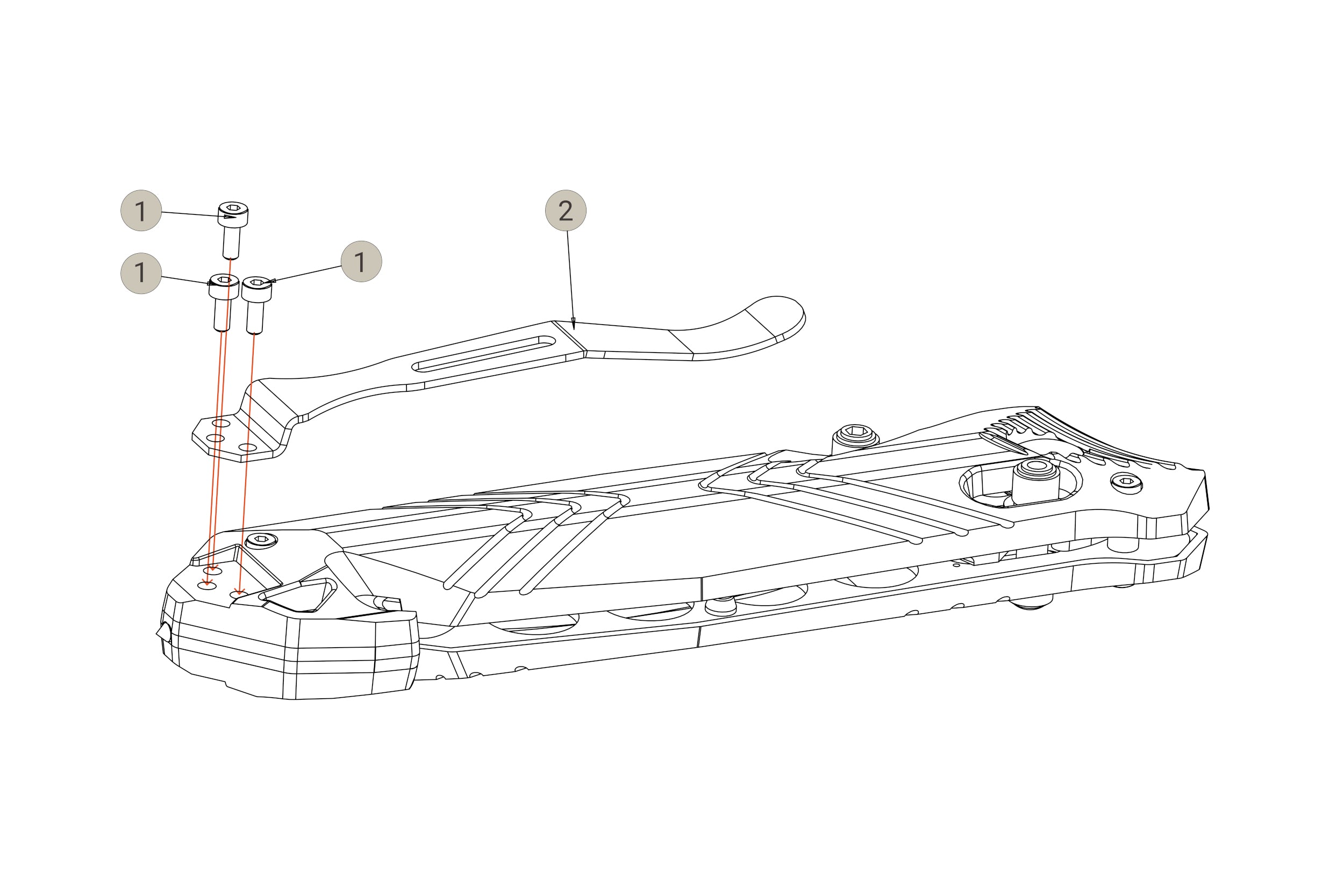

Changing the direction of use of the belt clip

The C.A.C.® knife is ambidextrous: In addition to the blade locking mechanism, which can be used by both right-handed and left-handed people, you can position the belt clip on the side of the knife that best suits your use. To reverse the belt clip mounting side, remove the 3 stainless steel screws (1). Position the belt clip (2) on the opposite side of the knife, then refit the 3 stainless steel screws (1). The application of thread lock on the screws, before tightening, is recommended to avoid any untimely unscrewing.

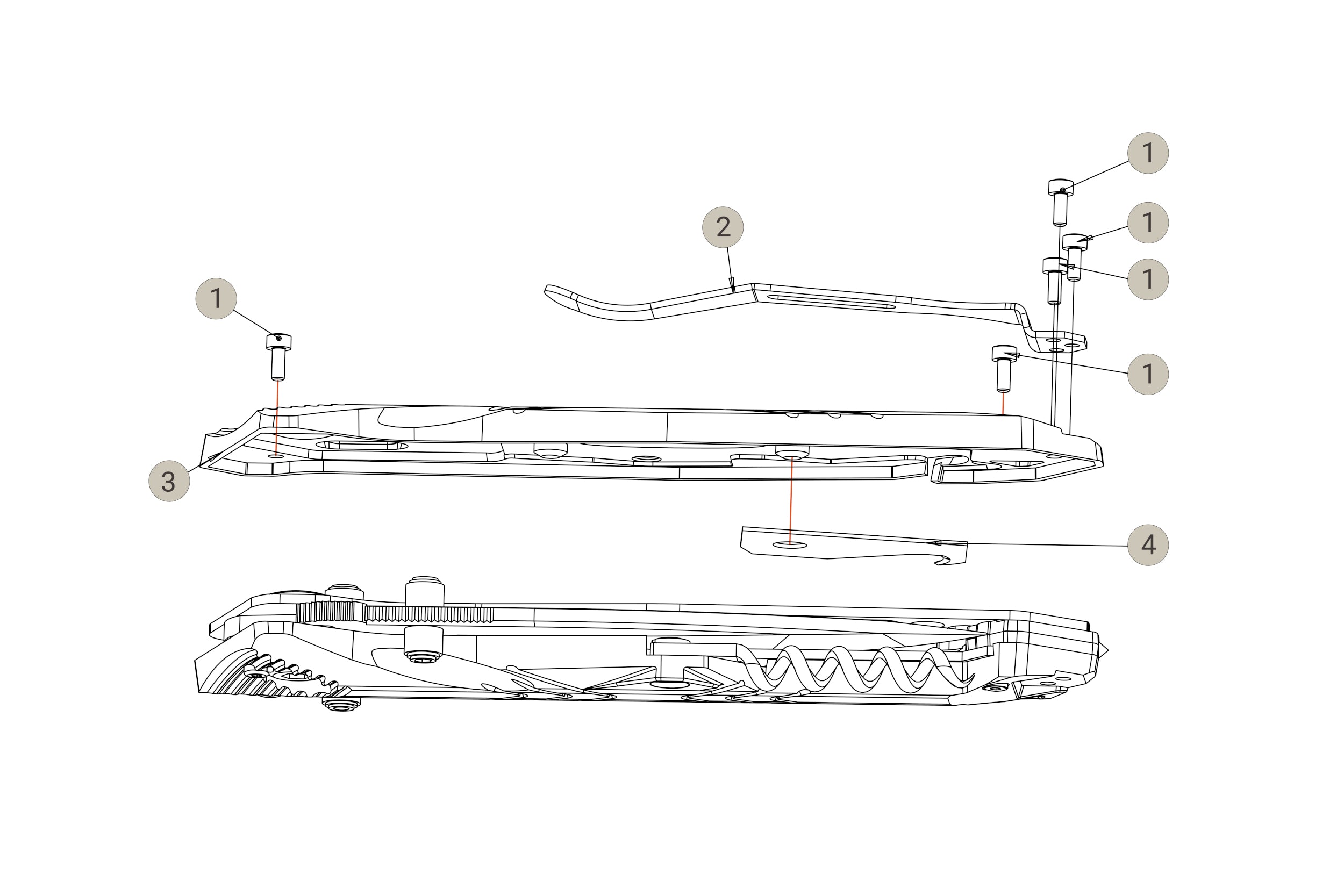

Replacing the strap cutter blade

If the belt clip (2) is mounted on the same side as the strap cutter (2), remove the 5 shiny stainless steel screws (1). Remove the belt clip (2) then remove the side of the handle (3). Replace the blade (4).

If the belt clip (2) is mounted on the same side as the corkscrew (3), remove only 2 shiny stainless steel screws (1). Remove dimension (3). Replace the blade (4). To reassemble your knife, proceed in the reverse order of the disassembly operations. The application of thread lock on the screws, before tightening, is recommended in order to avoid any untimely unscrewing.

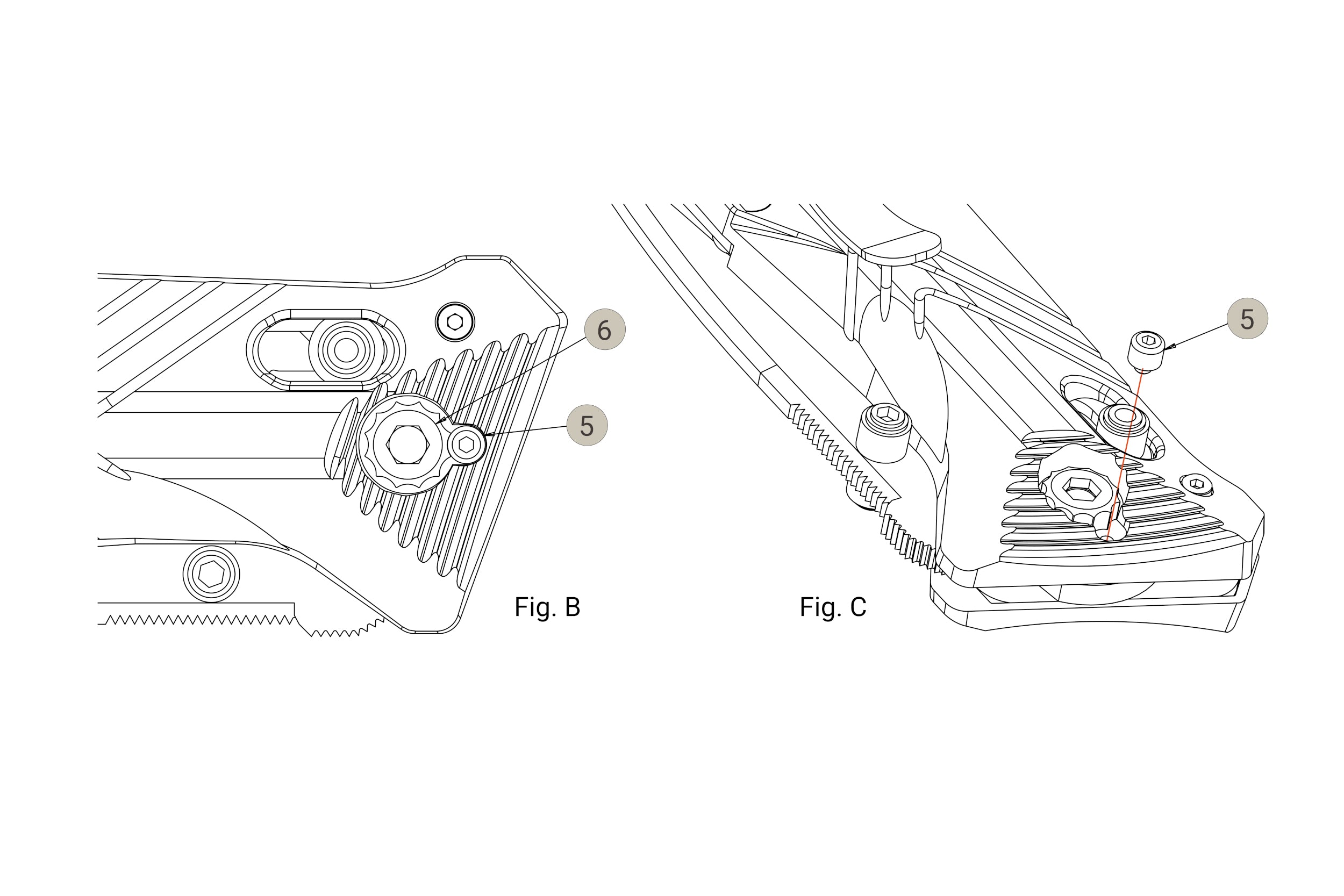

Blade clearance adjustment

After many hours of use, it is possible that a slight lateral play may be felt at the blade axis. To guarantee impeccable operation in all circumstances, the adjustment of the blade axis (6) is “locked” by a specific shiny stainless steel locking screw (5). To adjust, remove the locking screw (5), then tighten or loosen the blade axle (6) as necessary. Lock this new adjustment by repositioning the locking screw (5) in one of the notches on the axle (6) provided for this purpose. Applying thread lock to the screws before tightening is recommended. Caution: excessive tightening of the axle (6) will prevent the blade from being maneuvered effectively. Prefer a “free” adjustment simply intended to compensate for lateral play.